Articles

Keep up to date with the latest news and information from Bobier Metrology Solutions

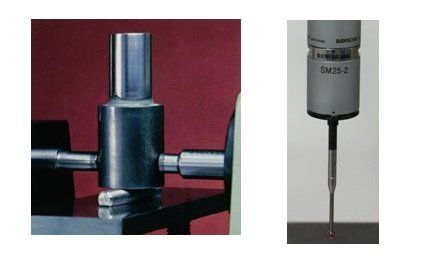

Your reputation depends on the dedication of your gage measurement providers. The 2-point bench gage used by many calibration companies takes as little as 2 points on your gage. Are you certain that your gage source is providing the sub-micron accuracies that are required in the new world’s accuracy environment? Bobier Metrology Solutions’ advanced method for gage certification scans your gage in order to collect thousands of points, increasing accuracy. This is how we can find the rejects. So again – How do you know if your gages are as accurate as they need to be? Here is one way: Send us your best certified working gage and enclose the results on this simple gage. We will provide you with an ISO certification for FREE. You may discover that your current gage source is not as accurate as it needs to be.

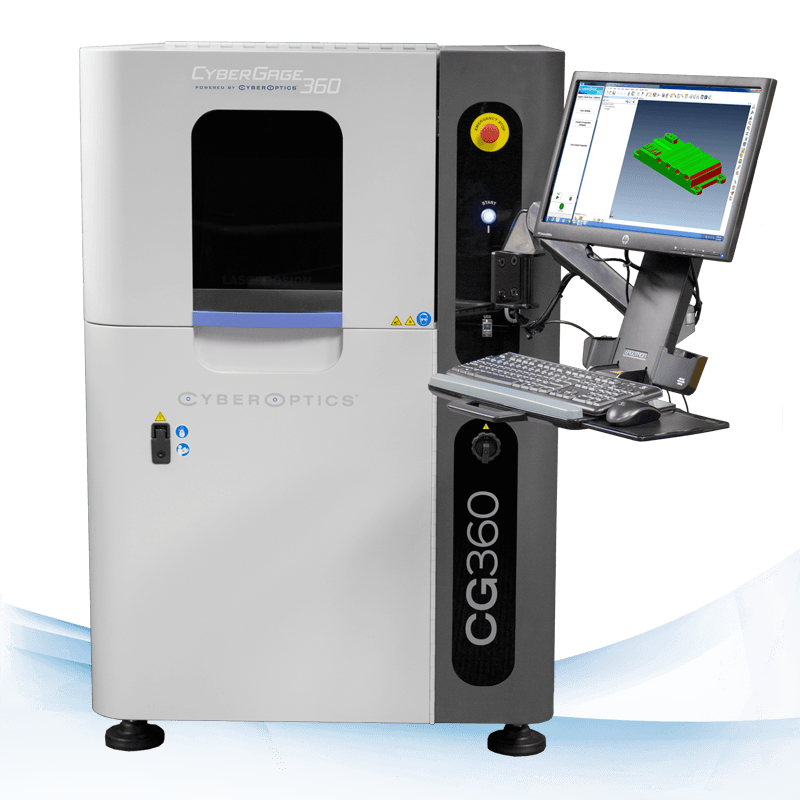

CyberGage360 is the newest inspection machine! CyberGage360 lowers cost and shortens time by dramatically speeding up in-process inspection and/or incoming/outgoing parts inspections High-Precision Accuracy with MRS Technology Quickly generates full 360° automated 3D surface scan with accuracy to 7µm, 0.007mm +L/10000mm Easy-to-Use with One-Button Simplicity Fast Scanning in Less than 3 minutes Work Volume: 200mm diameter x 100mm high cylinder (8″ diameter x 4″ high) Weight of Part: 4.4lbs max (2.0kg) System Controllers Embedded: High-performance PC included The CyberGage360™ has a range of applications from medical to automotive to aerospace to customer electronics, where high accuracy and high speed throughput are important. Unprecedented speed, accuracy, and one-button simplicity for non-contact automated 3D scanning inspection. Contact us today for more information on the CyberGage360.

NDI’s PRO CMM delivers accurate, reliable 3D measurements using a high-speed Optical Tracker, flexible Multi-Sided Probe and powerful Dynamic Part Referencing. PRO CMM Optical Tracker The PRO CMM can measure parts up to 7.5m in a single step with micron level accuracy throughout the measurement volume. It has no moving parts, making it a reliable and proven optical CMM, even outside the stable environment of a controlled quality lab. Dynamic Part Referencing (DPR) With Dynamic Part Referencing, an operator can simultaneously move the part, fixture, probe or scanner, even the Optical Tracker itself, and the system will maintain an accurate alignment. Unwanted motion is continuously measured and subtracted, without operator intervention. Multi-Sided Probe (MSP) Each Multi-Sided Probe is factory characterized to ensure accurate measurement regardless of probe orientation. When attached to a pre-calibrated Renishaw tip, you can easily probe visible or hidden features anywhere within the PRO CMM measurement volume. Contact us today for more information on the NDI! We are certified to ISO 17025 allowing us to certify your parts.