Bobier MetrologyRing Gage Certification

Tight deadlines and even tighter budgets may hinder your ability to provide on time and in budget dimensional inspection for new projects, capability study, or manufacturing process improvements.

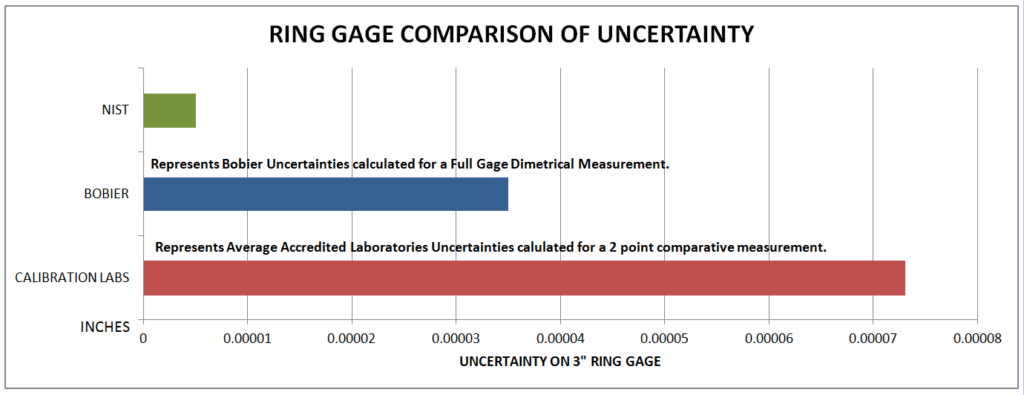

The above represents a comparison of Bobier Metrology Solutions to both NIST and an average of the uncertainties represented by accredited laboratories in the United States. Data was collected using posted “ISO/IEC 17025 Certificates of Accreditation” from three major accreditation bodies.

BOBIER offers several options of ring gage certification:

A ring gage certified at BOBIER is measured in our closely controlled laboratory that has double locked doors and is held to a temperature of 68° +/-1° F (20° +/-0.56° C) and 40% Humidity +/-5%, on our high accuracy Leitz PMM654. This machine has been retrofit with 5nm scales. Certified via laser calibration, with accuracy trending tracked for more than 5 years using our 30 year old reference block that validates linear distance, 2d dimetrical and 3d spherical outputs.

We are committed to providing the highest grade, most accurate certification possible outside of NIST!